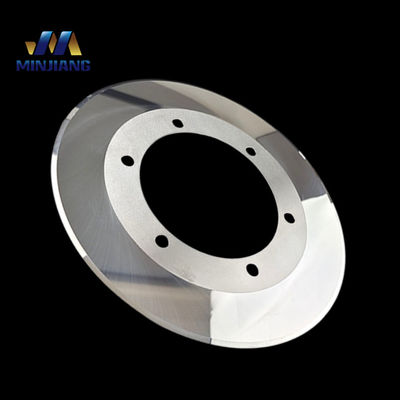

High Efficiency Lithium Electrode Battery Industry Knives Circular Slitting Blade

Circular slitting knives are specialized cutting tools designed for precision and accuracy. These knives are used to make precise cuts on materials such as paper, plastic, rubber, and metal. They come in a variety of shapes and sizes and can be used to create narrow strips, circles, and other shapes. Additionally, these knives are also capable of cutting intricate patterns and shapes into materials. With their versatility and efficiency, circular-slitting knives are essential tools for any production line. Not only are they effective, but they are also durable and easy to use and maintain. These knives are cost-effective and can be used on a variety of materials, making them the ideal tool for any production process.

Product Applications

Our Circular Slitter Blades are also ideal for many other industries, such as electronics, textiles, metalworking, and plastic processing. For these industries, our blades provide superior cutting quality and performance. We also specialize in making custom-slitting blades for unique applications, so you can rest assured that you will get the highest quality blades for your specific needs. Furthermore, our team of experienced engineers is available to provide you with the best possible advice on how to get the most out of your Circular Slitter Blades. We also offer a wide range of coating and heat treatment services to ensure that your blades remain sharp and in optimal condition throughout their lifetime.

Product Features

Non-magnetic properties: Non-magnetic properties refer to the ability of a material to not be attracted to a magnetic field, therefore making it suitable for use in areas near magnets, electronics, and other sensitive equipment. This property also increases the safety of workers in these areas.

Low coefficient of friction: This refers to the material's ability to move without the need for lubrication. This is ideal for oilfield operations because it allows for smoother operation and faster movement. Additionally, it reduces the risk of damage to the equipment due to friction.

Resistant to wear and corrosion: The material's resistance to wear and corrosion makes it perfect for use in oilfield operations. This ensures that the equipment is protected from damage due to the harsh conditions of the environment. Additionally, it ensures that the equipment remains reliable and durable over time.

Package

Company Profile

Chengdu Minjiang Precision Tool Co., Ltd. is a high-tech private enterprise that specializes in CNC carbide cutting tools, oil pipe thread cutters, carbide wear parts, and carbide non-standard product development and production. Established in 1992, the company employs 160 personnel and has six factories and a 10000-square-meter facility. It is ISO9001:2015 certified and strives to provide customers with efficient and high-quality products and services. The company also provides customized development services to meet the specific needs of each customer. With its dedication to innovation, Minjiang is dedicated to delivering superior products and services.

FAQ

1. Q: How long does it take for delivery?

A: Delivery time will depend on the shipping method selected, but typically takes between 4-10 days.

2. Q: What is the best way to contact you?

A: You can contact us by email, telephone, or online chat.

3. Q: Do you provide free samples?

A: We can provide free samples, but do not undertake the freight cost.

4. Q: Is the price competitive?

A: Yes, we offer reliable products at good prices.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!