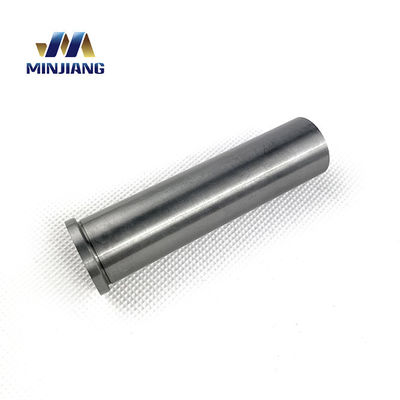

Durable Carbide Sliding Bearing Sleeve / Sintered Tungsten Carbide Bearing

Introduction

Tungsten Carbide Sleeves are essential pieces of equipment in the oilfield industry, providing extreme durability and power. Made from tungsten carbide, a very tough and dense material, they are capable of enduring high temperatures and pressures, forming a tight and secure seal that prevents any leakage of liquid or gas. Additionally, their low coefficient of friction and non-magnetic traits make them apt for high-pressure scenarios. Moreover, they are highly resistant to corrosion, making them ideal for drilling, production, and storage operations.

Product Overview

| Name |

Tungsten Carbide Sleeves |

| Applications |

Oil and Gas Industry |

| Dimensions |

Customized |

| Lead Time |

35 days |

| Material |

YG6/YG8/YG11/YG13 |

| Certificates |

ISO9001:2008 |

| MOQ |

20 PCS |

| Package |

Carton Box |

Product Features

High strength and hardness: High strength and hardness refer to the ability of an item to tolerate significant amounts of force and wear without deformation or breakage. This includes a high tolerance for physical impacts, as well as chemical and thermal exposure.

Extremely wear-resistant: Extremely wear-resistant materials are those that are able to withstand large amounts of wear and tear without showing signs of wear. This is especially important for parts that are subject to constant friction and abrasion, such as bearings and gears.

High-temperature resistance: High-temperature resistance refers to the ability of a material to withstand extreme temperatures without degrading or becoming brittle. This is especially important for parts that are subject to high temperatures, such as engine components and exhaust systems.

Excellent corrosion resistance: Excellent corrosion resistance is the ability of a material to resist corrosion caused by chemical or environmental exposure. This is especially important for parts that are exposed to harsh chemicals, such as those used in industrial processes or marine environments.

Innovation As Always

To remain competitive in this ever-evolving environment, Minjiang must stay ahead of the curve. By taking advantage of new technologies and processes, the company can create new solutions to existing challenges, and develop products and services that exceed customer expectations. Additionally, improving efficiency and productivity is a key component of staying ahead. Through the implementation of innovative methods, Minjiang can reduce costs and increase efficiency, allowing them to remain competitive in the marketplace. By fostering an atmosphere of creativity and innovation, Minjiang can ensure that they are ready to take advantage of any new ideas or opportunities that may arise.

FAQ

1. Q: What is your minimum order quantity?

A: Our minimum order quantity will vary depending on the product.

2. Q: Are the products high quality?

A: Yes. The raw material will be tested before bulk production, and we will check the physical properties, shape, and tolerance for ensuring qualified products before shipping.

3. Q: What is the best way to contact you?

A: You can contact us by email, telephone, or online chat.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!