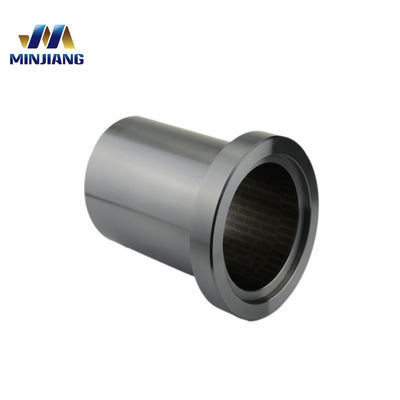

TC radial bearings are a type of bearing that is used to reduce friction and improve the efficiency of a rotating component. They are composed of two rings, an inner ring and an outer ring which are separated by a cage, and several balls that are held in place by the cage. The inner and outer rings are designed to rotate in opposite directions, and the balls spin freely between them. This design allows for smooth and efficient rotation without the need for lubrication or high maintenance. These bearings have a high load capacity and are used in a variety of applications, such as conveyor belts, electric motors, and other rotating machinery. As they are resistant to wear, they are also often used in applications where high precision is needed. They are also used in automotive, aerospace, and medical applications. TC radial bearings are designed to be durable and reliable, making them an ideal choice for a variety of applications.

Product Features

High Load Capacity: TC radial bearings are designed to handle high loads and shock loads, making them ideal for applications that require high load capacity.

Low Maintenance: TC radial bearings require minimal maintenance and lubrication, making them ideal for applications that require less maintenance.

High Durability: TC radial bearings are designed for long life and are highly resistant to wear and fatigue.

Low Friction: TC radial bearings are designed with low friction and low wear characteristics, making them ideal for applications that require low friction.

High Speed: TC radial bearings are designed to operate at high speeds, making them ideal for applications that require high-speed performance.

Product Structure

Quality Guarantee

At TC Radial Bearing, we guarantee quality and satisfaction with every purchase. We understand that our customers require precision and reliability from the products they purchase, and that is why we are committed to providing only the highest quality products. We are proud to say that all of our bearings are manufactured to the highest standards and feature superior construction and materials. We use only the best steel and other materials, and our products undergo rigorous testing to ensure they meet the highest quality standards. Our bearings are designed to provide superior performance and reliability in a range of applications. We are also committed to providing excellent customer service. Our knowledgeable and friendly customer service staff is available to answer any questions and provide support when needed. We also offer a full range of services including installation, maintenance, and repair. At TC Radial Bearing, we are passionate about providing the best quality products and services to our customers. We stand behind the quality of our products and services and guarantee that you will be satisfied with your purchase. We are committed to providing our customers with the best products and services and ensuring their satisfaction.

FAQ

1. Q: Do you provide samples? Is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

2. Q: Are you a trading company or manufacturer?

A: We are a manufacturer.

3. Q: How do you guarantee your quality?

A: Material selection and hardness survey are critical for product quality. We were formally engaged in forging and had a good command of the mechanics and properties of different tool steels. Inspection of incoming materials is furthermore well taken care of. Long-term raw providers physically near to us, help make us more competitive, ensured quality.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!