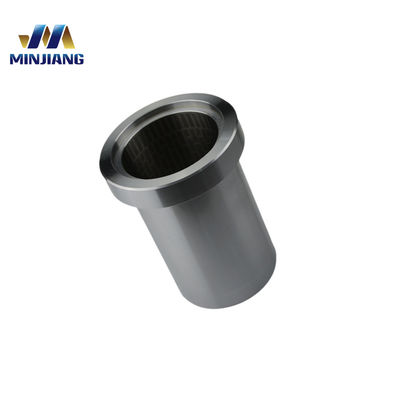

Good Compactness Custom Wear Resisting Long Lifetime Tungsten Carbide Tc Radial Bearing

The TC radial bearing is a high-performance component known for its exceptional reliability and excellent performance characteristics. Its precision engineering ensures smooth rotation and minimal friction, resulting in efficient operation and reduced energy consumption. The TC radial bearing's durable construction and advanced materials allow it to withstand heavy loads and harsh operating conditions, ensuring long-lasting performance with minimal maintenance. Its superior alignment and precise fit contribute to stability and accuracy in motion control applications. Whether used in automotive systems, industrial machinery, or precision instruments, the TC radial bearing delivers consistent performance and provides the necessary support for demanding applications.

Product Structure

Concept of Innovation

- Innovation is a process of making changes to existing products, services, processes, or business models.

- It involves taking risks and thinking outside the box to create and develop new ideas.

- Innovation can take many forms, from the introduction of new technologies to the rethinking of existing products and services.

- It is a key driver of economic growth and can help organizations stay ahead of the competition.

- Innovation is an ongoing process that requires creativity and innovation.

Minjiang has invested heavily in innovation initiatives to ensure their products remain on top of the competition and gain maximum profitability. Such initiatives include harnessing cutting-edge technology to optimize their production line, introducing new products, and investing in R&D. Furthermore, they are building up international collaborations, engaging in marketing and advertising activities, and creating new and improved distribution routes. All in all, the measures that Minjiang has undertaken are to ensure their products remain desirable to the market and stay profitable going into the future.

Company Objective

At Minjiang, we highly prioritize the value we provide to our customers. We continuously seek ways to enhance the quality of our products and services while always remaining mindful of their cost-effectiveness. By continually innovating and incorporating advancements in technology, we ensure that our customers receive the most cutting-edge solutions at competitive prices. Through our highly experienced team, we develop unique solutions that cater to our customers' specific requirements. We are dedicated to delivering excellence, maintaining affordability, building strong customer relationships, providing outstanding customer service, and ensuring our customers receive the utmost value for their money. Our ultimate goal is to ensure a positive customer experience that exceeds expectations.

FAQ

1. Q: Do you provide samples? Is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

2. Q: What is the lead time?

A: Lead time can vary depending on the product and quantity ordered but typically ranges from 1-4 weeks.

3. Q: How do you guarantee your quality?

A: Material selection and hardness survey are critical for product quality. We were formally engaged in forging and had a good command of the mechanics and property of different tool steels. Inspection of incoming materials is furthermore well taken care of. Long-term raw providers physically near to us, help make us more competitive, ensured quality.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!