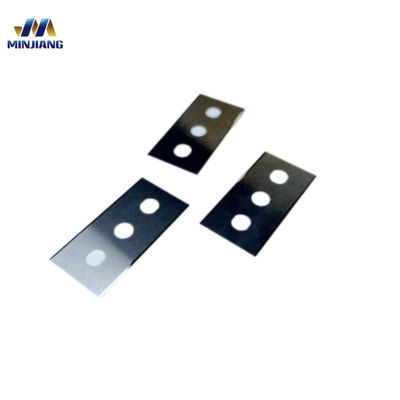

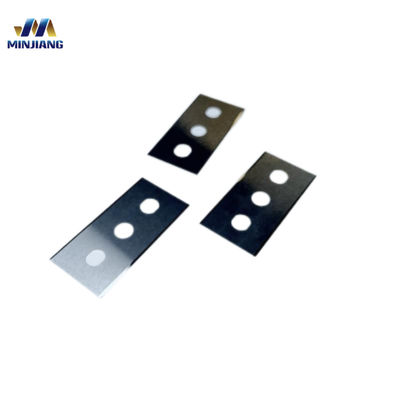

Mirror Polished Carbide Three Hole Slitter Blades Applied In Lithium Battery Cutting

Our three hole blades are the optimal choice for the lithium battery industry, combining advanced materials and precision engineering to deliver exceptional performance and reliability. By utilizing our blades, manufacturers can achieve higher efficiency, lower costs, and produce superior quality batteries that meet the stringent standards of the market.

Technical Advantage

With years of experience in cemented carbide material research and product development, we are able to customize high-performance raw materials according to the specific needs of our customers, ensuring that the quality and performance of our products meet the requirements of application scenarios in different industries.

Our company already has the ability to produce nanoscale carbide slitting knives, which have higher precision and wear resistance, and can significantly improve production efficiency and product quality to meet the needs of high-end markets.

For the lithium battery industry, we provide diamond and diamond-like coatings, which greatly enhance the hardness and wear resistance of the tools and enable them to maintain excellent performance under extreme conditions, thus extending their service life and reducing maintenance costs for customers.

Product Features

- Long Lifespan: The high wear resistance of carbide material significantly extends the blade’s lifespan, reducing the frequency of replacements and lowering operational costs.

- Efficiency: Enhanced cutting efficiency and reduced downtime result from the precision and durability of the blades, leading to increased productivity.

- Quality Consistency: Consistent, clean cuts ensure high-quality finished products, improving overall production standards.

- Stablization: Slitter knives are stabilized at high cutting speeds, reducing vibration and noise and improving the working environment and product quality.

Product Specification

| Length |

Width |

Thickness |

| 43 |

22 |

0.1 |

| 43 |

22 |

0.2 |

| 43 |

22 |

0.3 |

| 43 |

22 |

0.4 |

| 43 |

22 |

0.5 |

| 60 |

22 |

0.3 |

| 60 |

22 |

0.4 |

Company Concept

Creativity is key in the process of innovation. It is the ability to think outside the box and come up with new ideas, products, services, or processes that can create value. In order to stay ahead of the competition, organizations must be willing to take risks and explore new technologies and methods. Innovation is a dynamic process that requires a commitment to experimentation, testing, and adaptation. At Minjiang, we strive to foster a creative and innovative environment where our team of professionals can explore new ideas and develop cutting-edge solutions for our customers.

FAQ

1. Q: What is your minimum order quantity?

A: Our minimum order quantity will vary depending on the product.

2. Q: What payment methods do you accept?

A: We accept payment by bank transfer and Western Union.

3. Q: How long does it take for delivery?

A: Delivery time will depend on the shipping method selected, but typically takes between 4-10 days.

4. Q: Are the products high quality?

A: Yes. The raw material will be tested before bulk production, and we will check the physical properties, shape, and tolerance for ensuring qualified products before shipping.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!