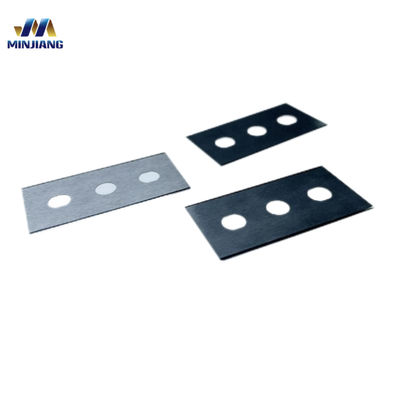

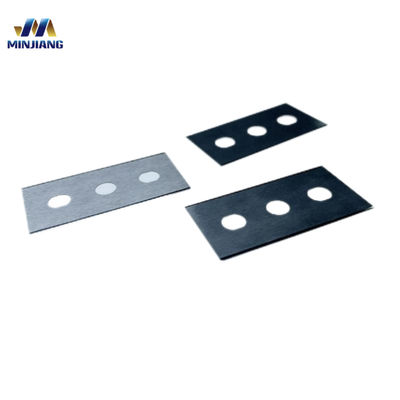

Enhancing Efficiency Tungsten Carbide Three Hole Blades For New Energy Sector

Product Introduction

Our three hole blades are the optimal choice for the lithium battery industry, combining advanced materials and precision engineering to deliver exceptional performance and reliability. Designed to meet the stringent standards of the market, these blades provide unparalleled precision and durability, ensuring manufacturers can achieve higher efficiency, lower costs, and produce superior quality batteries.

Process Advantages

1. Advanced Materials

Premium-Grade Carbide: Our blades are crafted from high-quality carbide, known for its exceptional hardness and wear resistance. This ensures a longer lifespan and consistent performance, even under the demanding conditions of high-volume production.

2. Exceptional Performance

Ultra-Sharp Cutting Edge: Featuring ultra-sharp cutting edges, our blades deliver clean and smooth cuts with minimal burr formation. This reduces material waste and ensures the integrity of electrode materials, which is essential for battery performance.

3. Customizable Options: We offer customization in blade dimensions, hole configurations, and coatings, allowing manufacturers to optimize blade performance for specific applications within the lithium battery production process.

4. Precision Engineering

Three Hole Design: The precise alignment and secure fastening provided by the three hole design minimize blade movement during operation. This leads to accurate and consistent cuts, which are critical for maintaining the quality and performance of lithium battery components.

Quality Guarantee

The forging process stands as a cornerstone in our quest to deliver blades of exceptional strength and durability. Our unwavering commitment to the intricacies of material selection, hardness assessment, and forging has borne high-quality blades that have garnered the acclaim of our esteemed customers. At the heart of our success is our profound dedication to the art of material selection and meticulous hardness evaluation in the blade manufacturing process.

Our team boasts a wealth of experience in the art of forging and possesses an intimate understanding of the mechanics and properties of various grades of tool steel. We take every measure to ensure the quality of our blades, commencing with a thorough inspection of all incoming materials. Fortuitously, our enduring relationships with local suppliers afford us competitive pricing, enabling us to forge all components of our blades—a distinction that sets us apart from many of our competitors.

Our unwavering commitment to the forging process has proven to be a judicious choice, as attested by the consistent praise from our customers for the unparalleled strength and durability of our blades. Through the synergy of careful material selection, rigorous hardness assessments, and the artistry of forging, we have rightfully secured our position as a leader in blade quality, continually setting new standards in the industry.

Specific Applications

- Electrode Cutting: Ideal for cutting cathode and anode sheets, our blades ensure precise dimensions and smooth edges, which are vital for efficient battery assembly and optimal performance.

- Separator Film Cutting: Perfect for cutting separator films with high precision, our blades maintain the material's integrity and functionality within the battery.

- Tab Cutting: Effective for cutting battery tabs, our blades provide clean and accurate cuts essential for reliable electrical connections.

Company Objective

Minjiang is an international company that provides a wide range of products and services to customers across the globe. Our team of experienced and knowledgeable professionals is dedicated to creating innovative solutions that meet the unique needs of our customers. Our mission is to provide the highest quality products and services at the most cost-effective prices. We value the importance of strong customer partnerships and strive to deliver exceptional customer service to ensure total customer satisfaction. We are committed to offering our customers the best value for their money and creating a positive customer experience.

FAQ

1. Q: Are you a trading company or manufacturer?

A: We are a manufacturer.

2. Q: Do you provide samples? Is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

3. Q: Are Circular Slitting Knives easy to maintain, and what is their expected blade life?

A: Circular Slitting Knives are designed for easy maintenance, and their blade life can vary depending on usage and materials cut. Proper maintenance and care can extend their longevity.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!