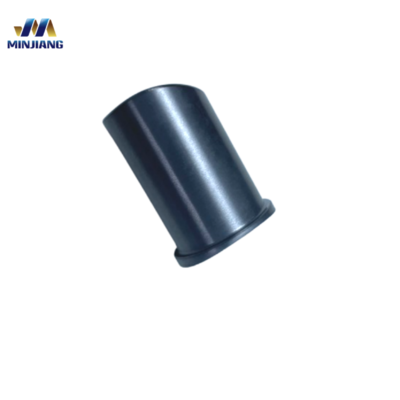

High-Wear Tungsten Carbide Sleeves for Industrial Protection & longevity

Description

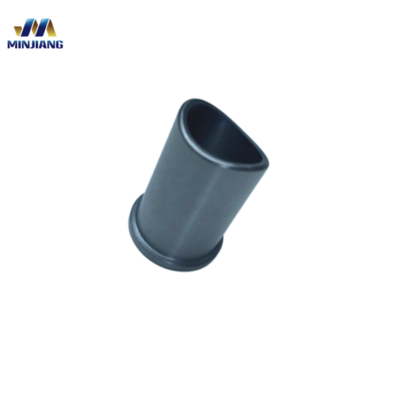

Our Tungsten Carbide Sleeves are engineered to deliver superior protection against abrasion, impact, and corrosion in demanding industrial environments. Made from high-grade tungsten carbide with optimized cobalt binding, these sleeves offer exceptional hardness and structural integrity under continuous mechanical stress. Ideal for use in machinery, pumps, valves, rotating equipment, and drilling tools, the sleeves significantly extend component life, reduce maintenance frequency, and enhance operational reliability. Available in standard and fully customizable sizes, each sleeve undergoes strict quality control—including dimensional checks, hardness testing, and microstructure analysis—to ensure consistent performance. Whether used in mining, construction, manufacturing, or slurry handling, our carbide sleeves provide a cost-effective solution to minimize wear and maximize uptime.

Specification

| Product Name |

Tungsten Carbide Sleeves |

| Usage |

Oil and Gas Industry |

| Dimensions |

Customized |

| Production Time |

35 days |

| Recommended Grade |

YG6/YG8/YG11/YG13 |

| MOQ |

Negotiable |

| Country of Origin |

China |

| Package |

Carton Box |

Product Features

- Exceptional Wear Resistance – Withstands severe abrasion, greatly extending service life.

- High Hardness & Strength – Maintains performance under heavy load and high stress.

- Impact Resistant – Excellent toughness reduces chipping and fracture risks.

- Corrosion Resistance – Reliable operation in harsh or corrosive environments.

- Customizable Designs – Tailored dimensions and grades to fit specific applications.

Innovation As Always

In a rapidly evolving industrial landscape, Minjiang recognizes that continuous innovation is crucial for maintaining leadership. The company proactively adopts advanced technologies and develops forward-thinking strategies to generate and implement innovative ideas and solutions. This approach enables Minjiang to devise creative responses to existing challenges, launch new products and services, and enhance current offerings. Moreover, by integrating cutting-edge processes, Minjiang significantly improves operational efficiency and productivity, while streamlining workflows and reducing costs. Committed to fostering a culture of innovation, Minjiang ensures it remains competitive and ready to capitalize on emerging opportunities.

FAQ

1. Q: What is the lead time?

A: Lead time can vary depending on the product and quantity ordered but typically ranges from 1-4 weeks.

2. Q: Do you provide samples? Is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

3. Q: Can you produce tungsten carbide products according to customer drawings?

A: Yes, we offer full custom manufacturing services. You can provide your designs or samples, and we will produce high-quality tungsten carbide products that meet your exact specifications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!