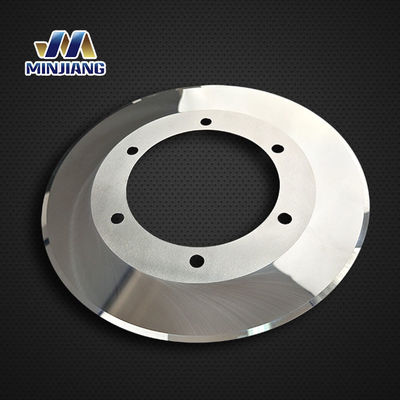

Manufacturer Corrugated Carton Paperboard Packing Machine Slitting Blade

A Packing Machine Cutting Blade is a vital component of any packing machine. It is the primary tool used to cut and seal packing material in order to create a secure package. It is made from high-quality steel and is designed to be durable and reliable. It is available in a variety of sizes and shapes to accommodate different types of packaging materials. Packing Machine Cutting Blades are used in a variety of industries, including food and beverage, pharmaceutical, and automotive. The cutting blade is a critical component of the packing machine and needs to be of the highest quality and precision in order to ensure reliable and consistent results. The cutting blade also needs to be designed with safety in mind, as it can be a hazardous piece of equipment if not used correctly. With proper maintenance and care, a Packing Machine Cutting Blade will provide years of reliable service.

Product Specification

| Description |

Dimension |

Blade Angle |

| Slitting Top Blade |

ϕ100×ϕ65×0.7 |

26°, 30°, 35°, 45° |

| Slitting Bottom Blade |

ϕ100×ϕ65×2 |

26°, 30°, 35°, 45°, 90° |

| Slitting Top Blade |

ϕ100×ϕ65×1 |

30° |

| Slitting Bottom Blade |

ϕ100×ϕ65×3 |

90° |

| Slitting Top Blade |

ϕ110×ϕ90×1 |

26°, 30° |

| Slitting Bottom Blade |

ϕ110×ϕ75×3 |

90° |

| Slitting Bottom Blade |

ϕ110×ϕ90×3 |

90° |

| Slitting Top Blade |

ϕ130×ϕ88×1 |

26°, 30°, 45°, 90° |

| Slitting Bottom Blade |

ϕ130×ϕ70×3/5 |

90° |

| Slitting Top Blade |

ϕ130×ϕ97×0.8/1 |

26°, 30°, 35°, 45° |

| Slitting Bottom Blade |

ϕ130×ϕ95×4/5 |

26°, 30°, 35°, 45°, 90° |

| Slitting Top Blade |

ϕ98×ϕ66×0.7/0.8 |

30°, 45°, 60° |

| Slitting Bottom Blade |

ϕ80×ϕ55×5/10 |

3°, 5° |

| Slitting Top Blade |

ϕ110×ϕ90×1 |

26°, 30° |

Product Features

Corrosion Resistance: Our products are resistant to corrosion and can withstand harsh environmental conditions.

Low Maintenance: Our products require minimal maintenance, allowing for improved operational efficiency.

Reliability: Our products are highly reliable and produce consistent results, promoting customer satisfaction.

Package

Company Advantages

Packing machine cutting blades are an essential tool for any industrial operation. Minjiang's cutting blades are designed for precision and accuracy, crafted with cutting-edge technologies and sustainable materials. This ensures that their customers are provided with the best cutting solutions for their packing needs. Minjiang is dedicated to innovation, staying ahead of the competition, and providing customers with cutting solutions that are both efficient and cost-effective. Their blades are designed to be both durable and reliable, providing customers with the perfect tool for their packing needs. With Minjiang's cutting blades, customers can have peace of mind knowing their products are being cut to the highest of standards. Minjiang is committed to continual improvement and innovation, ensuring its customers have access to the latest technologies and materials. With its dedication to innovation, Minjiang is able to provide its customers with a wide range of cutting solutions that are both reliable and cost-effective.

Quality Guarantee Measures

The forging process is crucial for the blades to be strong and durable. As a result of our focus on material selection, hardness survey, and forging, our blades are of high quality and have been well received by customers. We take great pride in our commitment to material selection and hardness survey when making our blades. Our team has extensive experience with forging and understands the mechanics and properties of various tool sheets of steel. We take extra precautions by inspecting all incoming materials and are fortunate to have longstanding suppliers nearby that offer us competitive prices. This allows us to forge all parts of our blades, while many of our competitors do not. Our commitment to forging has proven to be a successful choice; customers have consistently praised our blades for their strength and durability. Through careful selection of materials, hardness survey, and forging, we have established ourselves as a leader in blade quality.

FAQ

1. Q: What is your minimum order quantity?

A: Our minimum order quantity will vary depending on the product.

2. Q: What payment methods do you accept?

A: We accept payment by bank transfer and Western Union.

3. Q: How is the lifespan of blade?

A: According to different cutting applications, different blades would have different performance. Our blade always stands on high place. You will be satisfied with our quality.

4. Q: Are the products high quality?

A: Yes. Raw material will be tested before bulk production, and we will check the physical properties, shape and tolerance for ensuring qualified products before shipping.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!