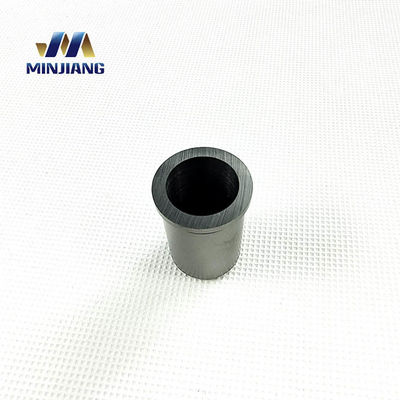

Oil Pump Carbide Bushing Sleeve Bearing Corrosion Resistance Long Service Life

Description

Tungsten carbide sleeves are an ideal solution for applications involving wear and abrasion resistance. They are made from a hard and wear-resistant material that is able to resist high temperatures and pressures. Additionally, tungsten carbide sleeves are corrosion and impact resistant, making them a great choice for industries such as mining, construction, and oil and gas. They are available in a range of sizes and shapes, making them suitable for a variety of applications. Tungsten carbide sleeves are most commonly used in heavy-duty equipment and machinery to provide a long-lasting, reliable solution. The sleeves are also resistant to thermal shock, meaning they can be used in applications that involve extreme temperatures. Tungsten carbide sleeves are easy to install and maintain, making them a popular and cost-effective choice for many industries.

Specification

| Product Name |

Tungsten Carbide Sleeve |

| Usage |

Oil and Gas Industry |

| Dimensions |

Customized |

| Production Time |

35 days |

| Recommended Grade |

YG6/YG8/YG11/YG13 |

| MOQ |

Negotiable |

| Package |

Carton Box |

| Material |

100% Virgin Tungsten Carbide |

Product Advantages

High Precision: Our company uses state-of-the-art CNC equipment to ensure accuracy and precision in the production of the parts. With this equipment, we are able to produce parts with very tight tolerances, allowing us to meet customer specifications.

Strict Tolerance: Our company has strict tolerances that we adhere to when producing our parts. This ensures that parts are uniform and meet the customer’s exact requirements.

Burr-Free: Our company uses high-precision CNC equipment to ensure that parts are burr-free. This eliminates the need for additional finishing processes, saving time and money.

Widely Applied: Our company is able to produce parts for a wide range of applications, from automotive to aerospace and medical applications. This allows customers to source a wide variety of parts from one source.

Quality Guarantee

Our Tungsten Carbide Sleeves are of the highest quality and are backed by our quality guarantee. All our Tungsten Carbide Sleeves are produced to meet or exceed industry standards and have been tested to ensure durability and longevity.

We guarantee our sleeves are free from defects in material or workmanship and will perform as designed. We understand the importance of having reliable and durable products, and that is why we stand behind all of our sleeves with our quality guarantee. We offer a 100% satisfaction guarantee on all our sleeves. If you are not fully satisfied with your purchase, simply return it and we will offer a full refund or exchange. In addition, we offer a limited lifetime warranty on all our sleeves. If any product fails to perform as designed due to a manufacturing defect, we will repair or replace the product free of charge.

At our company, we take pride in providing quality products and services to our customers and we want you to be completely satisfied with your purchase. That is why we offer our quality guarantee on all our Tungsten Carbide Sleeves.

FAQ

1. Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. Or it is 20-35 days if the goods are not in stock, it is according to quantity.

2. Q: Is the price competitive?

A: Yes, we offer reliable products at good prices.

3. Q: Are the products high quality?

A: Yes. The raw material will be tested before bulk production, and we will check the physical properties, shape, and tolerance for ensuring qualified products before shipping.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!