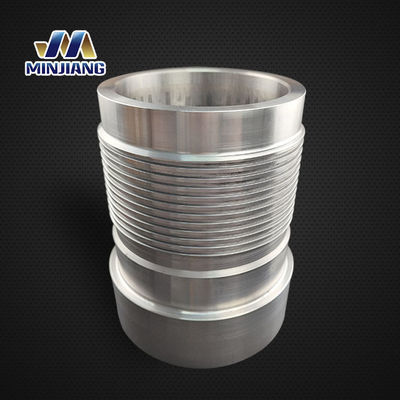

The Heavy-Duty TC Radial Bearing with PTA Tungsten Carbide Coating is a superior-grade component engineered for maximum durability and wear resistance in the most challenging industrial environments. This high-performance bearing incorporates a PTA-applied Tungsten Carbide layer, enhancing surface hardness and extending operational life under extreme stress and abrasive conditions. Designed for applications demanding consistent precision and strength, this bearing delivers exceptional radial load support and operational stability. Its advanced coating technology not only minimizes wear and friction but also ensures sustained performance in high-pressure and high-temperature settings. The Heavy-Duty TC Radial Bearing is an ideal solution for industries seeking long-term reliability and reduced maintenance cycles.

Product Features

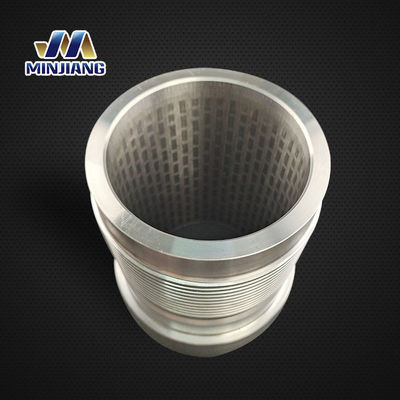

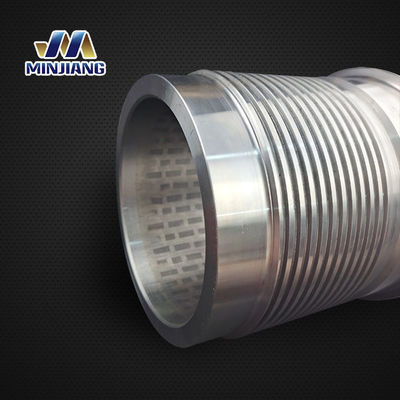

PTA Tungsten Carbide Coating: The precision-applied PTA coating delivers superior hardness and wear resistance, significantly enhancing the bearing’s longevity in abrasive and high-load applications.

High Load Endurance: Built to withstand heavy radial forces, this bearing performs reliably in demanding mechanical systems, including pumps, compressors, and rotating equipment.

Low Friction Operation: Engineered to reduce friction losses, this bearing supports smoother motion, improves efficiency, and lowers energy consumption.

Corrosion and Erosion Resistance: The PTA-coated surface provides excellent resistance against corrosive and erosive media, making it suitable for harsh operational environments.

Extended Service Life: With its reinforced construction and high-performance coating, the bearing offers long service intervals and reduced downtime, enhancing overall productivity.

Product Structure

Company Profile

Company Profile

Established in 1992, Chengdu Minjiang Precision Tool Corporation has emerged as a leading player in the realm of advanced technological solutions. As a premier private enterprise, our core expertise lies in the development and manufacturing of cutting-edge machining tools and high-performance wear-resistant components. Operating from our expansive 10,000 square meter facility located in the heart of China’s industrial hub, we boast a highly skilled workforce of over 100 professionals. Our fully integrated production line features state-of-the-art equipment, enabling us to maintain strict quality control while delivering precision-engineered products that meet the evolving demands of global markets.

FAQ

1. Q: Do you provide samples? Is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

2. Q: How does PTA differ from other hardfacing methods?

A: PTA offers greater control over dilution, coating thickness, and deposition rate compared to traditional welding or spray methods. It produces dense, crack-resistant coatings with excellent adhesion and minimal thermal distortion.

3. Q: How do you guarantee your quality?

A: Material selection and hardness survey are critical for product quality. We were formally engaged in forging and had a good command of the mechanics and properties of different tool steels. Inspection of incoming materials is furthermore well taken care of. Long-term raw providers physically near to us, help make us more competitive, ensured quality.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!