Corrosion-Resistant Tungsten Carbide Parts for Chemical Processing

Description

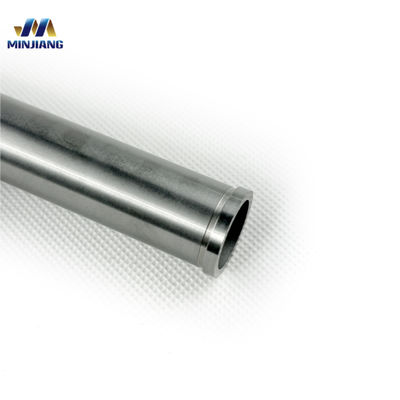

Tungsten Carbide Parts, renowned for their exceptional hardness and durability, stand as a pinnacle in material engineering for industrial applications. Comprising a combination of tungsten and carbon, these parts exhibit a Mohs scale hardness exceeding that of traditional steel, making them ideal for tasks demanding resistance to wear, abrasion, and high temperatures. The inherent toughness of tungsten carbide arises from its unique composition, where tungsten particles are cemented within a carbon matrix through a sintering process. This fusion results in a material that surpasses conventional metals in terms of hardness, ensuring prolonged service life even in the most challenging operating conditions. These parts find widespread utility in diverse industries, ranging from precision cutting tools in manufacturing to wear-resistant components in mining and drilling operations. Tungsten Carbide Parts are celebrated for their ability to maintain sharp edges, resist deformation, and withstand extreme conditions, including corrosive environments.

Specification

| Name |

Tungsten Carbide Parts |

| Applications |

Oil and Gas Industry |

| Dimensions |

Customized |

| Lead Time |

35 days |

| Material |

YG6/YG8/YG11/YG13 |

| Certificates |

ISO9001:2008 |

| MOQ |

20 PCS |

| Package |

Carton Box |

Product Advantages

- Optimal Thermal Conductivity: Tungsten carbide maintains optimal thermal conductivity, contributing to its performance in high-temperature applications.

- High Compressive Strength: The parts exhibit high compressive strength, ensuring stability under heavy loads and pressures.

- Low Coefficient of Friction: Tungsten carbide's low coefficient of friction minimizes resistance during operation, contributing to efficiency.

- Excellent Toughness: Despite its hardness, tungsten carbide parts display excellent toughness, preventing breakage or brittleness.

- Reduced Downtime: The longevity and durability of tungsten carbide parts contribute to reduced downtime, enhancing operational efficiency.

Source Supplier

Transparency in Processes: Purchasing directly provides transparency into the manufacturing processes. Customers can have a clearer understanding of the production methods, quality control measures, and ethical practices employed by the factory.

Reduced Lead Times: By eliminating middlemen, the supply chain becomes more streamlined. This reduction in complexity results in shorter lead times from order placement to product delivery.

Flexibility in Order Quantities: Direct purchasing often allows for flexibility in order quantities. Customers can place orders according to their specific needs without being constrained by preset quantities imposed by intermediaries.

Access to Technical Expertise: Establishing a direct relationship with the manufacturing plant provides access to technical expertise. Customers can seek guidance, ask questions, and receive valuable insights from professionals who are intimately familiar with the product.

FAQ

1. Q: What is the best way to contact you?

A: You can contact us by email, telephone, or online chat.

2. Q: Do you offer customized products?

A: Yes, we offer customized products to fit the client's demands.

3. Q: Can Tungsten Carbide Parts be customized for specific applications?

A: Yes, Tungsten Carbide Parts are highly customizable. Manufacturers often provide options for tailoring parts to specific dimensions, shapes, and tolerances to meet the unique requirements of different industries and applications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!