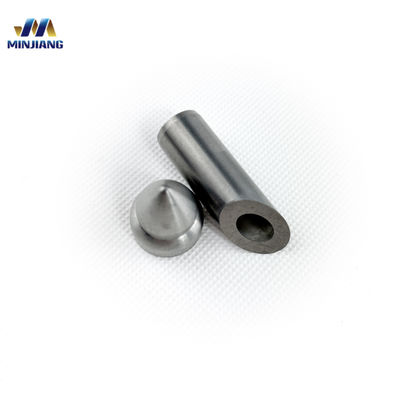

Durable Tungsten Carbide Cutting Tools for Industrial Machining

Description

Tungsten Carbide Parts stand out as exceptionally durable and versatile components, making them an ideal choice across various applications. Widely employed in industrial and commercial settings, these parts serve diverse purposes, including cutting tools, wear parts, dies, and punches. Their utility extends to medical and dental fields, benefitting from the remarkable hardness and strength inherent in tungsten carbide. The manufacturing process involves starting with tungsten carbide powder, shaped through a high-temperature sintering process. This method subjects the powder to extreme temperatures and pressures, essential for creating parts with unparalleled hardness and durability. Following sintering, the parts undergo machining, grinding, and polishing to achieve the desired size and shape, tailored to specific applications. Tungsten Carbide Parts are renowned for their exceptional strength, wear resistance, and hardness. Their resistance to corrosion makes them particularly suitable for deployment in challenging environments like chemical processing and oil and gas drilling. Moreover, these parts can serve as substitutes for other metals, such as aluminum and steel, addressing concerns related to weight and cost in diverse applications.

Specification

| Name |

Tungsten Carbide Parts |

| Applications |

Oil and Gas Industry |

| Dimensions |

Customized |

| Lead Time |

35 days |

| Material |

YG6/YG8/YG11/YG13 |

| Certificates |

ISO9001:2008 |

| MOQ |

20 PCS |

| Package |

Carton Box |

Supply At Source

- Reduced Lead Times: By eliminating middlemen, the supply chain becomes more streamlined. This reduction in complexity results in shorter lead times from order placement to product delivery.

- Flexibility in Order Quantities: Direct purchasing often allows for flexibility in order quantities. Customers can place orders according to their specific needs without being constrained by preset quantities imposed by intermediaries.

- Access to Technical Expertise: Establishing a direct relationship with the manufacturing plant provides access to technical expertise. Customers can seek guidance, ask questions, and receive valuable insights from professionals who are intimately familiar with the product.

Concept of Innovation

Minjiang is implementing various strategies to uphold competitiveness in the market and secure profitability. The company is making substantial investments in cutting-edge technology to enhance production efficiency, introduce innovative products, and actively participate in research and development endeavors. Moreover, there is a concerted effort to optimize advertising and marketing campaigns, establish novel distribution channels, and enhance the quality of existing products and services. These strategic initiatives underscore Minjiang's commitment to ongoing progress, positioning the company for success while maintaining a leading edge over competitors.

FAQ

1. Q: Do you provide free samples?

A: We can provide free samples, but do not undertake the freight cost.

2. Q: What is the best way to contact you?

A: You can contact us by email, telephone, or online chat.

3. Q: What is the benefit of using Tungsten Carbide Parts?

A: Using Tungsten Carbide Parts provides a number of advantages. It is renowned for its strong and durable properties, making it ideal for a variety of applications. It also offers a long service life and excellent performance even in harsh working conditions. Furthermore, it is highly resistant to corrosion, providing superior protection in wet or humid environments.

4. A: How do I maintain and extend the lifespan of Tungsten Carbide Parts?

Q: Proper maintenance involves avoiding extreme temperatures, providing adequate lubrication, and regular inspection for signs of wear. While Tungsten Carbide is known for its durability, following recommended maintenance practices ensures optimal performance and longevity.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!