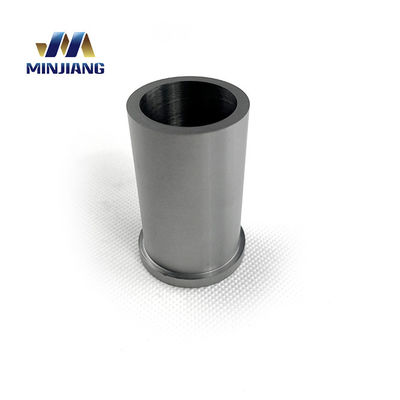

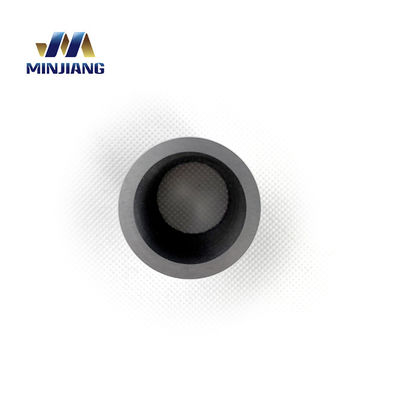

Wear Resistance Carbide Bushing Sleeve Bearing With 100% Raw Material

Introduction

Tungsten Carbide Sleeves are an essential component for oilfield operations, offering superior strength and hardness. These cylindrical components are made from tungsten carbide, a hard and dense material that provides excellent wear resistance. This allows them to be used in extreme temperatures and pressures, making them perfect for creating tight seals that prevent liquid and gas leakage in oil wells. They have non-magnetic properties and a low coefficient of friction, making them ideal for use in high-pressure applications. Additionally, these sleeves boast excellent corrosion-resistant properties, making them highly durable and reliable for use in drilling, production, and storage operations.

Specification

| Name |

Tungsten Carbide Sleeve |

| Applications |

Oil and Gas Industry |

| Dimensions |

Customized |

| Lead Time |

35 days |

| Material |

YG6/YG8/YG11/YG13 |

| Certificates |

ISO9001:2008 |

| MOQ |

20 PCS |

| Package |

Carton Box |

Product Features

Suitable for extreme conditions: High-pressure applications require specialized materials and components that are suitable for the extreme conditions of the environment. They must be able to withstand extreme temperatures and pressures, as well as the wear and tear of the environment and any other factors that may affect the operation. The materials and components must also be able to maintain their strength and integrity in order for the application to perform optimally.

Ideal for challenging operations: An application that can handle the pressure, temperature, and other conditions of the environment, as well as the torque and pressure needed to complete a challenging operation, is ideal. The material and components used must be able to withstand extreme temperatures and pressures, as well as the stress and wear of the environment and any other factors that may affect the application. In addition, the materials and components should be able to withstand corrosion and other forms of damage.

Competitive Pros

High-Quality Control: This refers to the quality control process that goes into making the parts. We inspect each part at every stage of production to ensure that the highest quality product is being delivered to our customers.

Abrasion Resistance: This refers to the ability of the parts to resist wear and tear during use. The parts need to be able to withstand the tough materials they are cutting through and remain strong.

Heat Treatment: This refers to the heat treatment process that is used to improve the strength and hardness of the parts. By using heat treatment, we can increase the strength and durability of the parts.

Surface Treatment: This refers to the process of treating the surface of the parts to increase the lifespan. This includes polishing and coating the parts to protect them against wear and tear.

FAQ

1. Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. Or it is 20-35 days if the goods are not in stock, it is according to quantity.

2. Q: Do you provide samples? Is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

3. Q: What is the benefit of using Tungsten Carbide Sleeves?

A: Tungsten carbide sleeves improved wear resistance, increased strength and durability, and improved corrosion resistance. They are also more dimensionally stable than other materials and can withstand higher temperatures, making them suitable for use in a wide range of applications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!