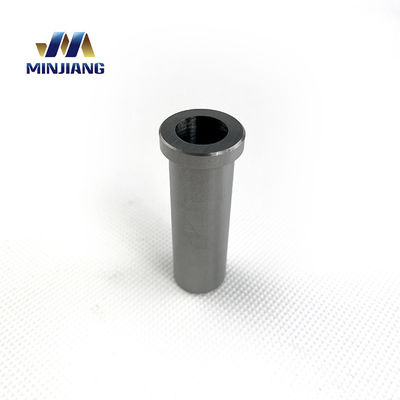

Tungsten Carbide Wear Parts Cemented Carbide Spacer Sleeve For Oil Industry

Description

Tungsten Carbide Sleeves are cylindrical components used in oilfield operations for their strength and hardness. Made from tungsten carbide, these components possess an incredibly high wear resistance, allowing them to withstand extreme temperatures and pressures. They are perfect for creating tight seals that prevent liquid and gas leakage in oil wells and boast non-magnetic properties with a low coefficient of friction. This makes them perfect for high-pressure applications. Additionally, their corrosion-resistant properties make them highly durable and reliable for use in drilling, production, and storage operations.

Specification

| Product Name |

Tungsten Carbide Sleeve |

| Usage |

Oil and Gas Industry |

| Dimensions |

Customized |

| Production Time |

35 days |

| Recommended Grade |

YG6/YG8/YG11/YG13 |

| MOQ |

Negotiable |

| Country of Origin |

China |

| Material |

100% Virgin Tungsten Carbide |

Product Features

Resistant to wear and corrosion: Materials that are resistant to wear and corrosion are beneficial for oilfield operations. These materials are able to withstand the harsh conditions found in oilfields, such as extreme temperatures, high pressure, and high concentrations of chemicals. They are also able to resist the effects of corrosion, which can cause damage to machinery and structures over time.

High thermal conductivity: High thermal conductivity is the ability of a material to transfer heat efficiently. Materials with high thermal conductivity are ideal for oilfield operations, as they can help keep equipment cool and reduce the risk of overheating and malfunctions. This property is also beneficial in industries such as automotive, aerospace, and defense, as it can help reduce energy consumption and costs.

Ideal for oilfield operations: Materials with a low coefficient of friction, non-magnetic properties, and resistance to wear and corrosion are ideal for oilfield operations. These materials can reduce the energy needed to move objects through oil, prevent corrosion and wear on machinery, and provide a safe environment for workers.

Innovation As Always

Innovation is critical to staying competitive in the ever-evolving business landscape. With the ability to come up with fresh solutions to existing issues, craft new products and services, and improve existing ones, Minjiang is able to maintain an edge over its rivals. Additionally, embracing the latest technologies can help to improve efficiency and productivity, as well as help to cut costs. Therefore, it is vitally important for Minjiang to foster a culture of innovation and create plans to recognize and put into practice new concepts and approaches.

FAQ

1. Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. Or it is 20-35 days if the goods are not in stock, it is according to quantity.

2. Q: Is the price competitive?

A: Yes, we offer reliable products at good prices.

3. Q: Are the products high quality?

A: Yes. The raw material will be tested before bulk production, and we will check the physical properties, shape, and tolerance for ensuring qualified products before shipping.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!